Many of the world’s leading brands have announced commitments to incorporate more post-consumer resin (PCR) in their packaging within the next 5-10 years. This sentiment is echoed by companies in a variety of industries around the world. Post-consumer resin is one solution to curbing the growing plastic pollution problem and decreasing the depletion of natural resources.

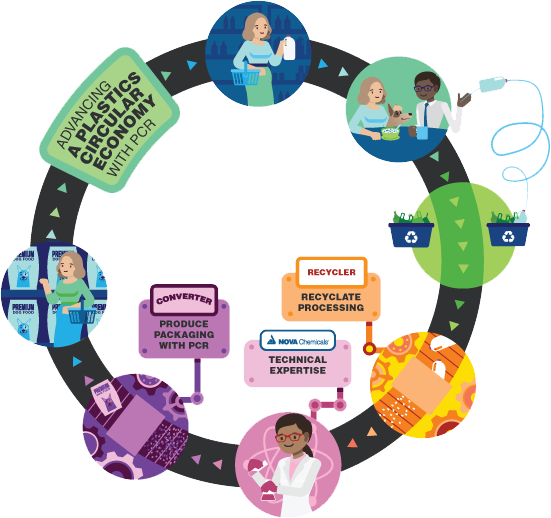

To meet the rising demand for post-consumer resin, the return and recycling of specific types of used, empty plastic packaging by consumers is key. One of the ways Mauser Packaging Solutions addresses the increased need for post-consumer resin and supports the transformation from a linear to a circular packaging industry is through our integrated life cycle management program, which includes collection, reconditioning, recycling and manufacturing of products from PCR materials.

So, what is post-consumer resin, how is it made, and what are the benefits?

What is Post-Consumer Resin (PCR)?

According to the International Organization for Standardization’s (ISO) “Plastics Vocabulary” list, post-consumer or post-use material, is defined as “material generated by the end-users of products, that has fulfilled its intended purpose or can no longer be used (including material returned from within the distribution chain).” This differs from post-industrial, or pre-consumer material which is defined as “material diverted during a manufacturing process”.

Post-consumer resin (PCR) includes consumer packaging items such as plastic film, bottles, milk jugs, buckets, and also industrial packaging items such as IBC totes and poly drums. These items can be reprocessed into recycled plastic that’s used to make new products.

How is PCR manufactured at Mauser Packaging Solutions?

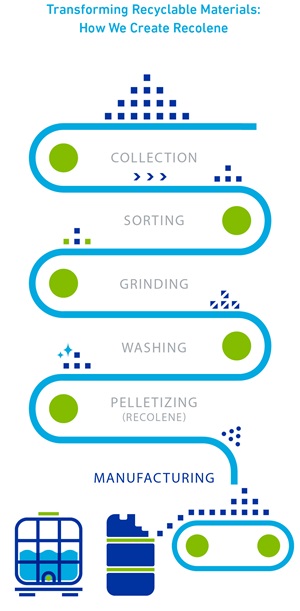

When an IBC or plastic drum reaches the end of its usable life and is no longer suitable for reconditioning, the first step in the recycling process is collection through the Mauser Packaging Solutions collection program. Empty containers and used plastic components are then sorted, shredded, ground, washed, dried and repelletized as high-quality post-consumer resin in compliance to ISO 16103:2005 standards. We call this in-house generated PCR “RecoleneTM.”

RecoleneTM, our premium recycled resin, is used to manufacture our own components and packaging, such as the Infinity Series of products. It offers the same benefits of reusability and recyclability as virgin resin and comparable technical performance. In 2019 alone, Mauser Packaging Solutions generated more than 51,000 metric tons of post-consumer resin from empty IBCs and plastic drums returned through our collection program.

What are the benefits using PCR?

Post-consumer resin offers a lower carbon footprint compared to virgin materials. Use of PCR diverts waste from landfills, decreases the consumption of virgin raw materials, and reduces emissions while promoting the circular economy.

How can your company contribute?

With such high demand for recycled materials, collaboration among the supply chain with the packaging manufacturer, filler and end user is extremely important to establish a true circular economy. To learn how you can participate in our global collection program of IBCs, plastic and steel drums, contact us